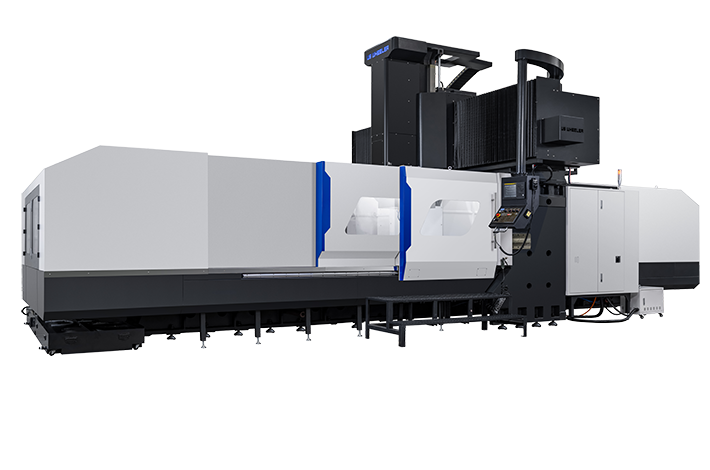

Gantry Machining Center LM8032

This series, featuring high rigidity, and flexible and convenient operation, is suitable for machining box-type parts, large sheet metal parts and molds, and supports multiple processes of parts such as milling, boring, drilling (drilling, expanding, ream

This series is widely applied in automotive, construction machinery, home appliance mold and mold base processing industries and other industries, and is also suitable for machinery manufacturing industry and other manufacturing industries.

Parameter Specifications

| Item | Gantry Machining Center LM8032 | Specifications |

|---|---|---|

| Travel | X-axis travel | 8000mm |

| Y-axis travel | 3200(full travel 3800)mm | |

| Z-axis travel | 1250mm | |

| Distance from spindle end face to worktable | 300-1550mm | |

| Gantry passing height | 1730mm | |

| Gantry width | 3200mm | |

| Worktable | Worktable size | 8000*2500mm |

| T-slot quantity/size/spacing | 11*28*200(两侧2*28*180) | |

| Maximum loading capacity | 30000kg | |

| Spindle | Spindle speed | 50-6000rpm |

| Drive mode | Belt drive | |

| Spindle motor torque (rated/maximum) | 140/223N·m | |

| Main motor power | 22/26Kw | |

| Servo axis | X/Y/Z rapid traverse speed | 8/10/10m/min |

| Cutting feed rate | 1-6000mm/min | |

| Counterbalance method | Nitrogen counterweight | |

| Minimum feed | 0.001mm | |

| Tool/tool magazine | Tool magazine type | ATC tool magazine (optional) |

| Shank specification | BT-50 | |

| Max tool length | 300mm | |

| Main accuracy | Positioning accuracy(X/Y/Z) | 0.045/0.025/0.018mm |

| Repeatability(X/Y/Z) | 0.025/0.015/0.012mm | |

| Others | Machine footprint and height | 20300*6970*5470 |

| Machine weight (apx.) | 97000kg | |

| CNC system | FANUC 0iMF PLUS |